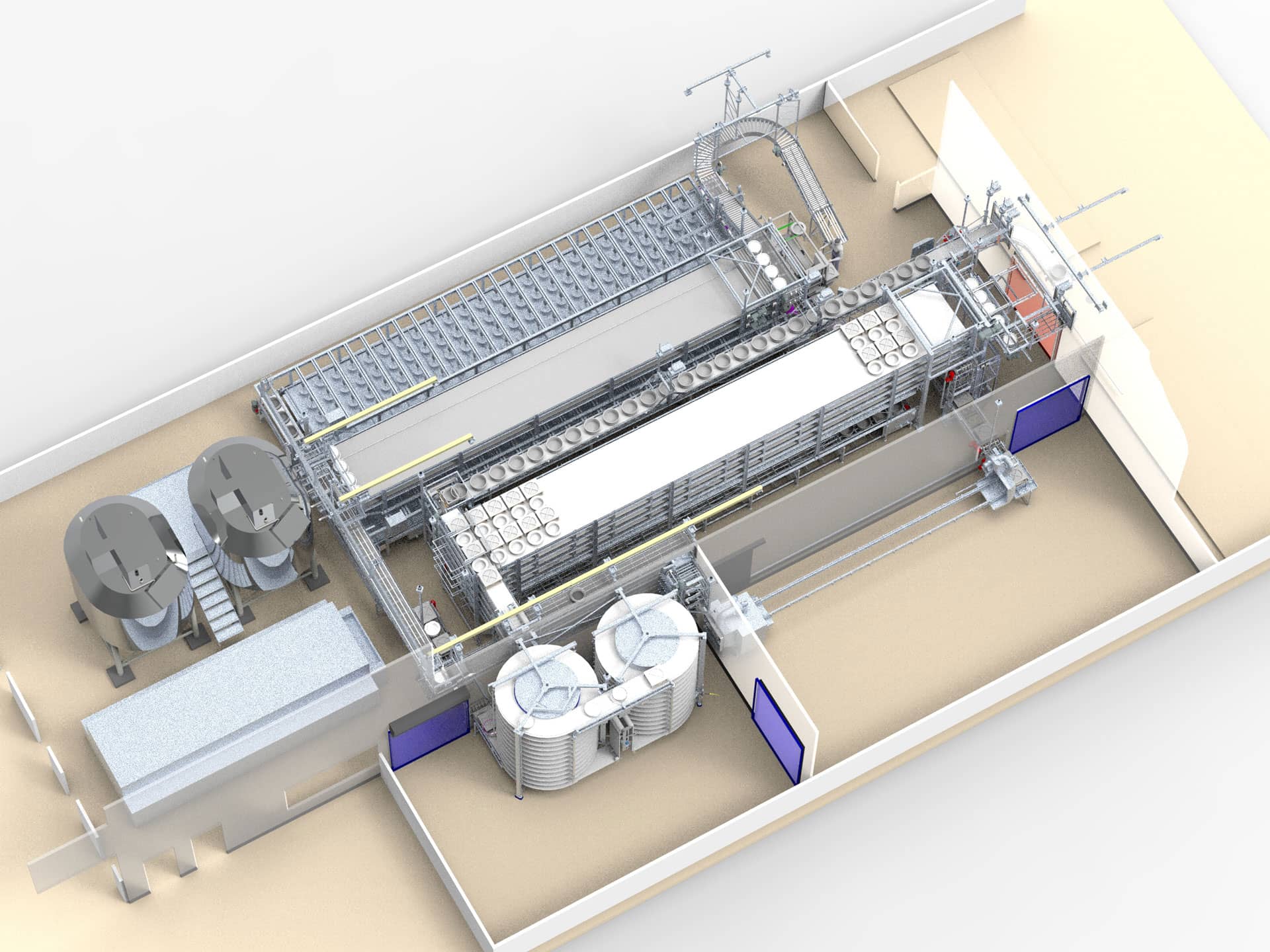

Optimal distance for fast packaging

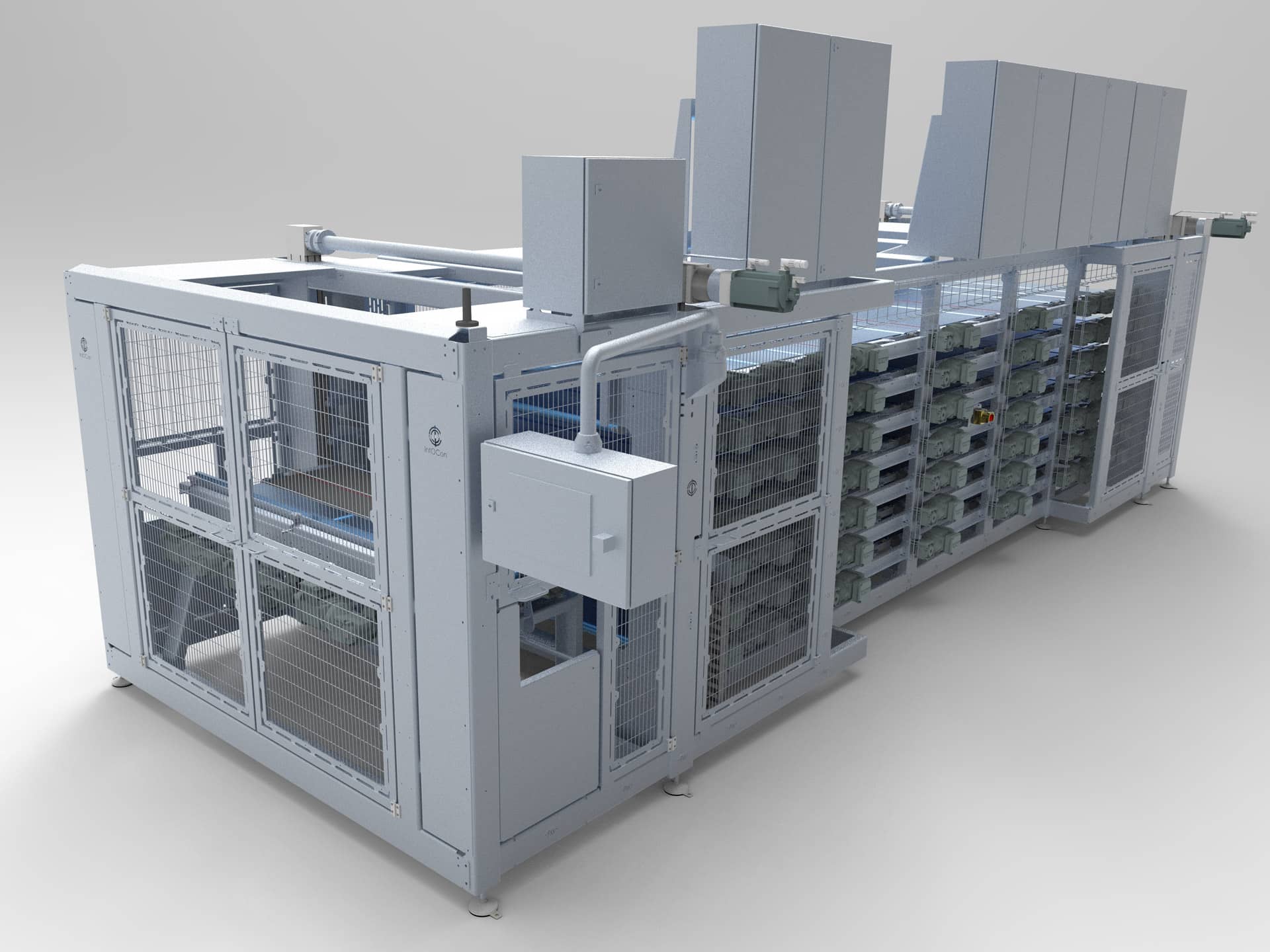

To optimize the packaging of chocolate bars, a customized machine was designed where the perfect distance is created between chocolate bars to utilize the maximum capacity of the packaging machine. Separation between the bars is initially provided by means of multiple conveyor belts. Then the bars are perfectly aligned by adjustable lateral guides and come back closer to each other just prior to entering the packaging machine.

Adjustable for a variety of dimensions

In order to use the machine on the full range of chocolate bars, often with different sizes, the lateral guides can easily adjusted to the smallest precision without tools. This is done by laser engraved indications and setting positions.

No chocolate powder in the packaging

The entire packaging process is controlled down to the smallest detail. A blow-off unit, mounted on the line just before the bars enter the packaging machine, prevents possible chocolate powder from entering the packaging.