Continuity of the production line ensured

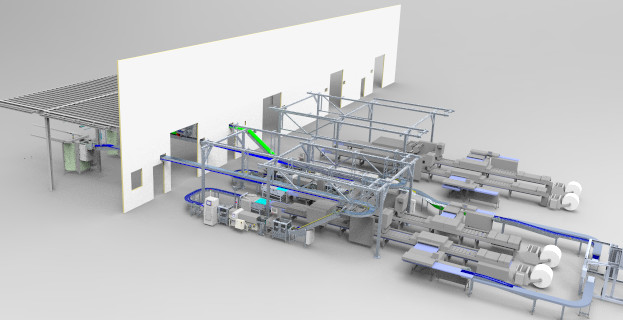

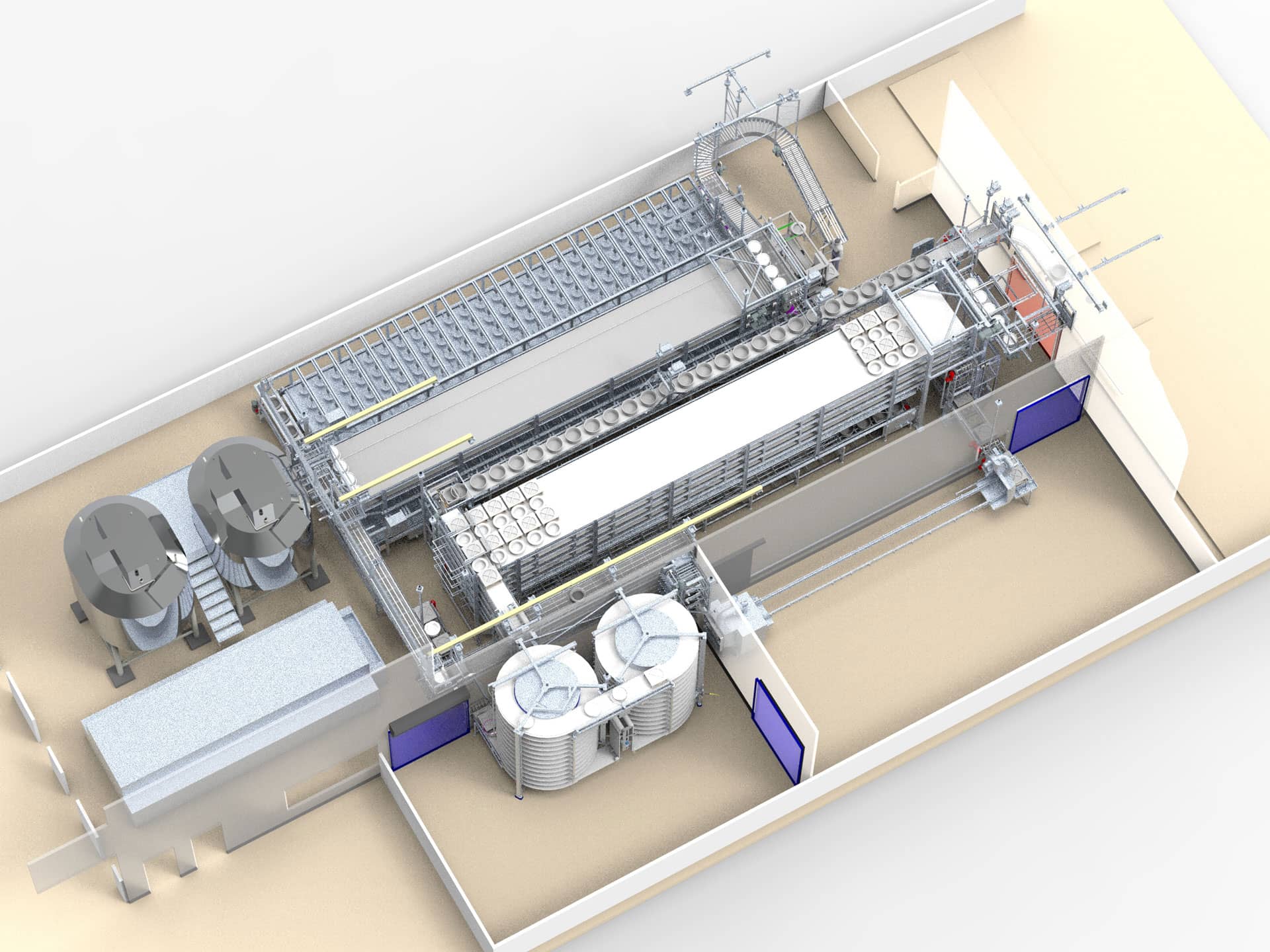

To ensure production continuity, IntOCon designed and built efficient buffer systems between the lines continuously producing stacks of wraps and the thermoforming packaging machines.

When the packaging process is interrupted, e.g. to replace an empty roll of film, the wraps are automatically buffered. Once the interruption is taken care of, the buffer automatically empties and wraps are transported to the packaging machines. This technology can be applied for a he variety of products.

Test with wraps in production environment

The buffer consists of an elevator system that divides the stacks into 5 or 7 levels, depending on the number of wraps per stack. To ensure a perfect transition between the different conveyors, a test demo unit was built and used during production.

In this way, the true actual condition of the product was tested before building the buffer. In this way, there was 100% certainty that the stacks passed seamlessly from one conveyor belt to the next.

Discover more realisations ...

Doubling of production, buffering and storage capacity of cheese moulds for the ...

View realisation